Saturday, April 27, 2013

Wednesday, April 24, 2013

No excuses

http://media-cache-ec4.pinimg.com/550x/75/3b/86/753b860ed44dcb0f80243400b006b722.jpg

Buffing wheels made from old shirts.

Friday, April 19, 2013

Visit to Prinsloo

Yesterday I went to visit a knife maker that I met at DEKS; Mr P Prinsloo. I'm very sorry for not taking my camera, I wasn't sure If he would be comfortable with me taking photos of his set up. That aside, he showed me his workshop and wow what a neat space you would think it's a German watchmakers shop. He was so welcoming, even gave some handle materials. We had a long chat about my stuff and what he does and he let in on some trade secrets. He said ,paraphrase ," you're doing very well for one starting out, and taking on stuff like this(holding my Puuko). It's encouraging". Towards the end of my visit we went into his home and chatted further about my jewellery and knife making future and he gave some of his blade magazines! The two bland pieces of handle material from the left, a piece of bamboo flooring and on the right a piece of African rosewood and in the top corner some rams horn from Bethlehem in South Africa. I left that visit very excitted and Mr Prinsloo said I was always welcome to come by and visit to ask questions.

Me spark testing

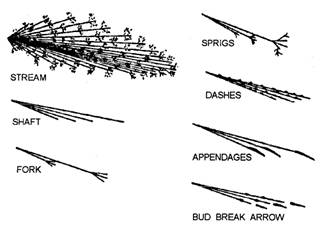

Just out of of curiosity I wanted to do some spark testing of some scrap steel I had in my work shop. It felt like discovering hidden treasure, I found some decent pieces for what I would be making.Here below are some pictures of what I used as a guide.

|

| http://maritimesecurity.asia/free-2/maritime-security-asia/how-to-identify-metals-in-engine-room-observation-and-spark-test/ |

|

| http://www.tpub.com/steelworker1/5.htm |

Spark test

(A) Wrought iron

(B) Mild steel

(C) Steel with 0.5 to 0.85% carbon

(D) High-carbon tool steel

(E) High-speed steel

(F) Manganese steel

(G) Mushet steel

(H) Special magnet steel

http://en.wikipedia.org/wiki/Spark_testing

(B) Mild steel

(C) Steel with 0.5 to 0.85% carbon

(D) High-carbon tool steel

(E) High-speed steel

(F) Manganese steel

(G) Mushet steel

(H) Special magnet steel

http://en.wikipedia.org/wiki/Spark_testing

Wednesday, April 17, 2013

Tuesday, April 16, 2013

Stress Fracture

I found a stress fracture on my blade, just after I had finished the blade and handle getting them ready to epoxy together. I decided to complete the knife as a trail run. I was highly disappointed but I learned that if the blade is unevenly heated if heat treating with a torch, stress fractures will occur.

Sent via my BlackBerry

Sent via my BlackBerry

What it is meant to look like

This is what the air rifle is supposed to look like, all the exposed metal parts were heavily pitted and rusted. According to all the gun specialists, one is never to use abrasives to restore a gun. Unfortunately I did but it's looking okay, and I used good old vinegar to dissolve all the rust off all the screws and pins. I did not want to soak the barrel and spring chamber in vinegar for fear of the insides becoming sticky.

Sunday, April 14, 2013

B9 air rifle

A friend of mine gave me an old B9 air rifle he found in the shed at his place. I'm going to restore it and get it shooting. Ill post a picture of the rusty pile later

Sent via my BlackBerry

Sent via my BlackBerry

Saturday, April 13, 2013

My New Blade

Today I bought myself a No.8 opinel folding knife. I'm trading in my "tsotsi" knife for a classy french workman knife.

Sent via my BlackBerry

Sent via my BlackBerry

Tuesday, April 9, 2013

Pipe

I finally finished this pipe, I have learned valuable lessons about pipe making. This was a very enjoyable venture, if I ever get any orders for more or another I will have to make adjustment to my tools. A wood lathe would cut shaping time in half, but Hand shaping is also satisfying. I will take A better picture tomorrow. It's looking good though, isn't it?

Puuko Time

I am ready to start on my puuko, in this picture I have my piece of Oak for my handle. The Oak is from Hilton, From the big storm of December 2012 that felled many tree around PMB. The steel I will be using is a VW golf 3 tire rod. I assumed that because it is a car part the steel would be high tensile and able to hold an edge because car parts have to with stand high amounts of tension. I'm very excited

for the forging.

Sunday, April 7, 2013

Ring pistol

Look at this Cool ring pistol, looks like an antique

http://www.oobject.com/12-concealed-guns/ring-pistol/6383/

Saturday, April 6, 2013

My next project

This is the next project I posted about in an earlier post. I would like to forge a Puuko, which could also be used as a whittling knife. A puuko is a working knife. the blade is disproportional to the handle to give stability when working. The knife should remain razor sharp, a blunt whittling knife can be dangerous. Blunt on wood is still sharp on flesh.

It's coming along

Its almost finished, the bowl and shank are roughly shaped. I still need to make the stem from this piece of Rhodesian teak. I am yet to come up with a solution for the tenon, I was thinking of carving it out of the same piece of teak. The problem I am needing to solve is the one of how to carve the tenon perfectly cylindrical without a wood lathe. I will be keeping you posted.

Subscribe to:

Posts (Atom)